In today's fast-paced logistics industry, efficiency and safety are paramount. Warehouses are evolving rapidly, and businesses are increasingly turning to artificial intelligence (AI) to optimize operations. AI-driven warehouse intelligence systems offer significant improvements in forklift and worker monitoring, goods inspection, and safety automation. By leveraging AI-powered solutions, warehouses can enhance productivity, reduce errors, and create a safer working environment.

AI-driven warehouse intelligence integrates machine learning, computer vision, and IoT sensors to monitor and optimize various warehouse activities. These technologies help improve efficiency, minimize risks, and ensure smooth operations by offering real-time data analysis and predictive insights.

AI-powered forklifts are equipped with cameras, sensors, and AI algorithms that assist in navigation, obstacle detection, and collision prevention. These forklifts can automatically adjust their routes based on warehouse traffic, ensuring seamless operations and reducing the chances of accidents.

AI-driven systems track worker movements, monitor fatigue levels, and detect unsafe behaviors such as improper lifting techniques or lack of personal protective equipment (PPE). Real-time alerts notify managers if safety protocols are breached, helping to prevent injuries and ensuring compliance with workplace safety regulations.

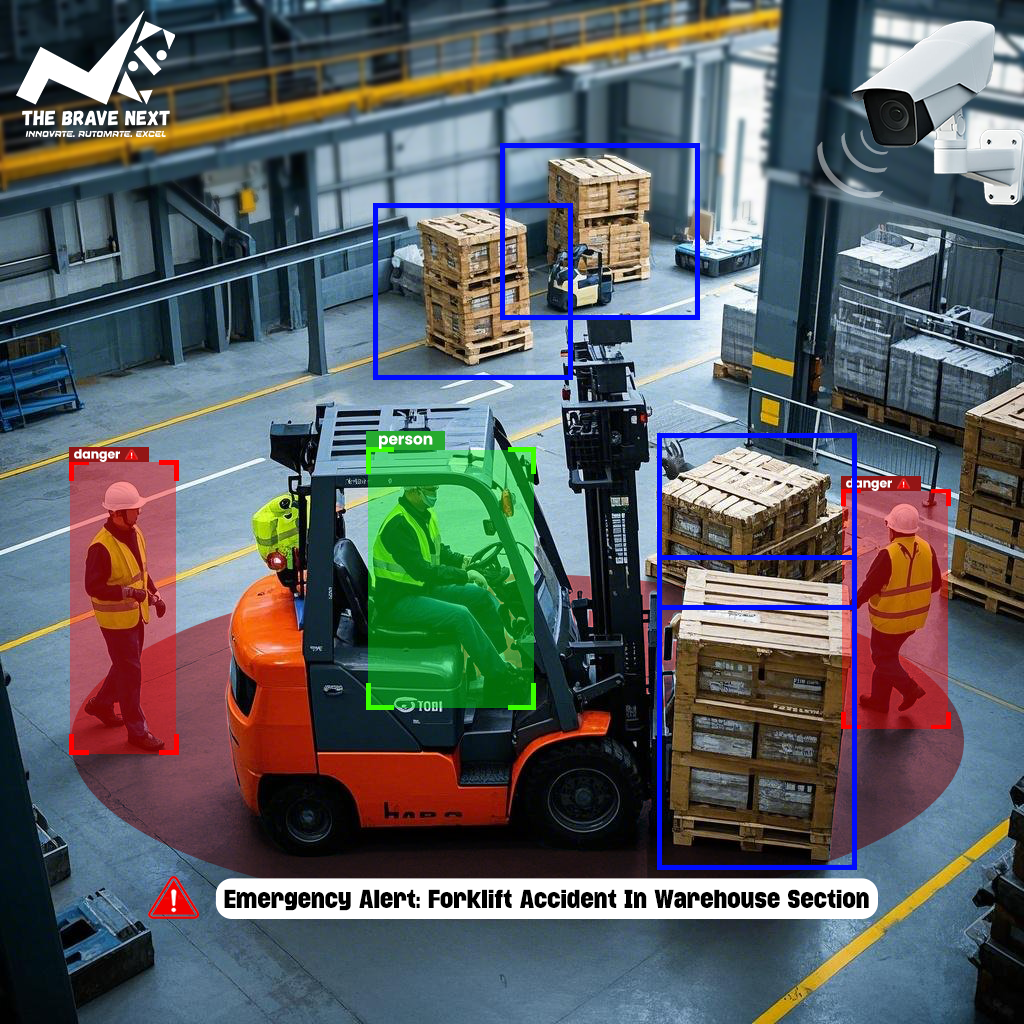

Forklift safety is a major concern in warehouses, where even small mistakes can lead to serious accidents. Traditional safety methods often miss critical risks like unsafe distances, parking errors, or forklifts moving too close to workers. AI-powered solutions address these issues with real-time hazard detection, proactive alerts, and continuous monitoring.

AI hazard detection systems play a vital role in identifying safety risks before they escalate into accidents. These systems continuously monitor high-traffic zones and risk-prone areas to identify potential dangers. Immediate alerts allow forklift operators to take corrective actions, preventing collisions and injuries. Warehouses that have adopted AI-powered surveillance systems report significant decreases in forklift accidents, showcasing the effectiveness of real-time hazard detection.

AI CCTV systems not only detect hazards but also monitor forklift operations to ensure compliance with safety protocols. These systems identify safety violations such as speeding, reckless driving, or improper load handling. The collected data helps warehouse managers analyze safety trends and operator behavior, allowing them to provide targeted training programs to forklift operators, improving overall safety and efficiency.

Traditional manual inspections are time-consuming and prone to errors. AI-powered cameras and computer vision technologies enable automated goods inspection, identifying damaged, defective, or misplaced items with high accuracy. This reduces human errors and enhances quality control.

AI-driven RFID (Radio-Frequency Identification) and IoT-based solutions help track inventory in real time. These systems provide instant updates on stock levels, expiration dates, and shipment status, improving overall supply chain visibility and efficiency.

AI-powered surveillance systems can detect potential hazards such as spills, obstacles, or fire risks. Automated alerts ensure that safety measures are promptly implemented, reducing workplace accidents and minimizing downtime.

In case of an emergency, AI systems can trigger automated responses, such as sending evacuation alerts, shutting down equipment, or directing emergency personnel to the affected area. This enhances crisis management and improves workplace safety.

AI-powered inventory management systems use predictive analytics to forecast demand, reduce overstocking, and prevent stockouts. Machine learning algorithms analyze sales trends, seasonal demand, and warehouse storage capacity, ensuring optimal inventory levels. This helps businesses streamline supply chain operations and improve customer satisfaction.

Autonomous robots are transforming warehousing by automating repetitive tasks such as picking, packing, and sorting. AI-driven robotics systems improve efficiency, reduce manual labor costs, and enhance accuracy in order fulfillment. These robots work alongside human workers, optimizing warehouse operations and increasing throughput.

AI optimizes warehouse workflows, reducing operational delays and improving overall productivity.

Continuous monitoring ensures compliance with safety protocols, reducing accidents and workplace injuries.

AI-driven automation minimizes human errors, reducing financial losses due to damaged goods or inefficient operations.

AI analytics provide valuable insights that help managers make informed decisions for warehouse optimization.

AI solutions can be adapted to warehouses of all sizes, making them a valuable investment for businesses looking to expand operations.

As AI technology continues to advance, we can expect even more sophisticated warehouse intelligence solutions. The integration of AI with robotics, augmented reality (AR), and blockchain will further enhance efficiency, security, and transparency in supply chain operations. AI-driven warehouses are not just a vision of the future—they are a reality transforming the logistics industry today.

AI-driven warehouse intelligence is revolutionizing the logistics industry by enhancing forklift and worker monitoring, goods inspection, and safety automation. By leveraging AI-powered solutions, businesses can improve efficiency, ensure workplace safety, and optimize inventory management. As technology continues to evolve, AI will play an even more critical role in shaping the future of smart warehouses, driving innovation, and boosting overall operational performance.

AI enhances warehouse safety through real-time monitoring of workers, forklifts, and potential hazards. AI-driven systems can detect unsafe behaviors, fatigue, and lack of protective equipment. Additionally, AI-powered surveillance and emergency response systems help prevent accidents and provide instant alerts in case of emergencies.

Yes, AI-powered inventory management optimizes stock levels using predictive analytics, preventing overstocking and stockouts. This minimizes waste, reduces storage costs, and enhances supply chain efficiency, ultimately lowering operational expenses.

AI-driven robotics automate repetitive tasks such as picking, packing, and sorting, increasing efficiency and accuracy. They reduce labor costs, enhance productivity, and minimize human errors, leading to faster order fulfillment and improved customer satisfaction.

Please send your query or requirements in detail via whatsapp, and we will respond shortly.

Thank you!