Personal Protective Equipment (PPE) is a fundamental component in maintaining safety across industries such as construction, manufacturing, healthcare, and more. However, manual PPE compliance checks are time-consuming, error-prone, and often inconsistent. That’s where AI-powered PPE detection systems come in — transforming workplace safety through automation, precision, and real-time monitoring. In this blog, we explore how AI is revolutionizing PPE compliance and creating safer work environments.

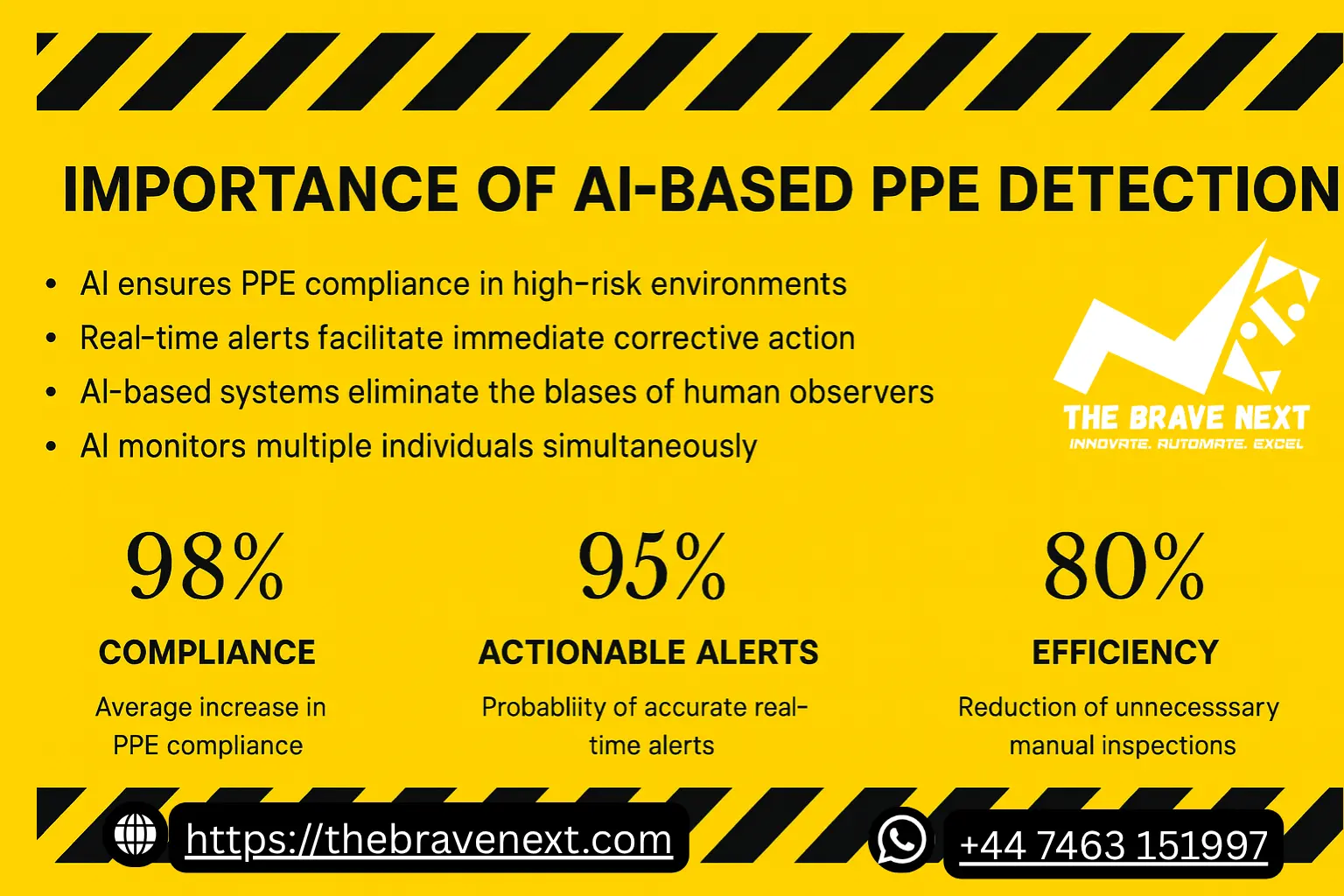

AI-powered PPE detection refers to computer vision systems that use artificial intelligence to detect whether workers are wearing proper safety gear — such as helmets, vests, gloves, goggles, and masks. These systems analyze real-time video footage and instantly identify PPE violations with remarkable accuracy.

Traditional safety audits rely on human oversight, which can miss violations due to fatigue, distractions, or limited visibility. Moreover, regular inspections only provide snapshots of compliance. AI systems, on the other hand, offer continuous 24/7 monitoring, significantly reducing human error.

AI-based PPE detection systems are built using computer vision models trained on large datasets of workers wearing various PPE. These models learn to identify specific gear in different lighting, angles, and environments, making them robust across diverse workplace conditions.

One of the biggest advantages of AI in PPE detection is real-time alerting. When a violation occurs — such as a worker entering a hazardous zone without a helmet — the system instantly sends notifications to supervisors, allowing immediate corrective action.

By catching violations instantly and ensuring consistent safety compliance, AI systems help reduce the number of accidents caused by missing PPE. This proactive approach directly contributes to lower injury rates and fewer workplace fatalities.

Many AI PPE systems can integrate with existing CCTV cameras and security infrastructure. This means companies don’t need to install new hardware — they can simply upgrade their software, making adoption cost-effective and scalable.

AI platforms not only detect violations but also collect and analyze safety data over time. Managers can view reports showing violation trends, high-risk areas, and frequent offenders, which helps in targeted training and improved safety policies.

Industries such as construction, oil & gas, mining, warehousing, and chemical manufacturing are already leveraging AI-powered PPE detection. These sectors deal with hazardous environments, where consistent PPE usage is critical to safety compliance.

As with any surveillance technology, AI-based PPE detection raises privacy questions. Companies must ensure transparent use, secure data handling, and proper communication with workers to foster trust and ethical implementation.

Looking ahead, AI-powered PPE detection will likely integrate with IoT devices, wearable tech, and predictive analytics, creating a holistic safety ecosystem. These smart safety systems will not only monitor but also predict risks, ushering in a new era of proactive protection.

Our in-depth analysis of AI-driven workplace safety has been featured across respected publishing and industry platforms. You can explore the full article on:

AI-based PPE detection systems are highly accurate, often exceeding 90% precision depending on the model and quality of training data. Their ability to analyze diverse lighting conditions, camera angles, and different PPE types ensures reliability across various industrial environments.

Yes. Most modern AI PPE detection solutions are designed to integrate seamlessly with existing surveillance systems. They use video feeds from current CCTV setups, reducing the need for new hardware installations and keeping deployment cost-effective.

While legal compliance varies by region, responsible implementation ensures safety and privacy. Companies should clearly communicate monitoring practices, anonymize data where possible, and store video footage securely to comply with data protection regulations and maintain worker trust.

Please send your query or requirements in detail via whatsapp, and we will respond shortly.

Thank you!